Panelized construction, or “panelization,” is redefining how we think about building, reimaging the homes we build, and redesigning the entire design/build process.

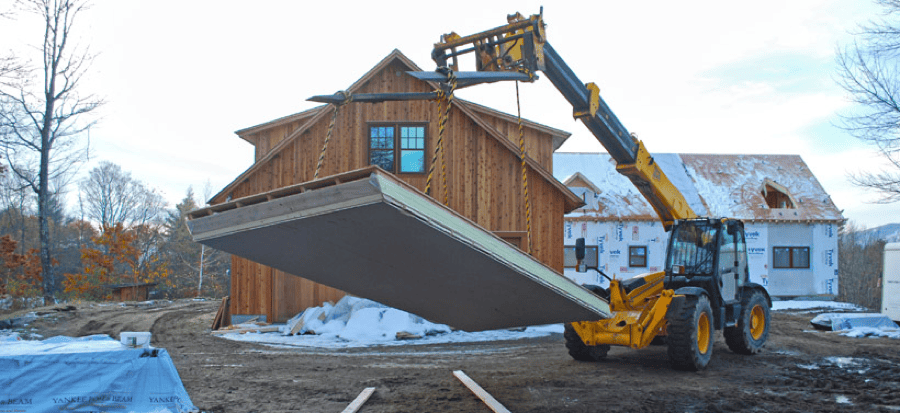

Panelized building systems are reshaping the residential home building industry from the ground up. Walls, trusses, roofs, and floor systems are precision constructed under controlled conditions in an off-site factory, protecting building materials from weather related damage onsite, or other potential setbacks.

These systems allow you to maintain a tight construction schedule, expedite the building process, reduce the likelihood of delays and necessary onsite labor, while at the same time cutting building costs by an estimated 10 to 15 percent, and material inputs by nearly 15 to 20 percent.

Your Dream Realized, One Panel at a Time

Contractors and builders are still stick framing traditional houses with hammer and nail from architectural blueprints, and building incredible homes every day.

Now imagine if you and your builder could set out to design your custom home to the most exacting architectural specifications using the latest computer technology, then, in addition, having the components of your new home onsite within a week to be constructed.

Panelization systems offer just that kind of flexibility, coordination, and customization potential. State-of-the art, climate-controlled factory/workshops and specialized technologies produce panels from your designs that are built to the highest quality standards, ensuring your home is built precisely square, dimensionally correct, and incomparably consistent.

Increased Efficiency All Around

Increased efficiency is much more than simply ENERGY STAR® lighting fixtures; much, much more. Panelized construction significantly expedites the construction process overall, streamlining both onsite and offsite labor, increasing efficiency at every stage of the process; site work is completed at the same time the panel components are being manufactured offsite. That means:

- More consistent quality and construction.

- Less material waste on the jobsite.

- Maximized efficiency in material inputs.

- Reuse of what would have previously been waste materials.

- Dramatically expedited building process from months to a matter of days.

For these reasons and many more, the National Association of Home Builders, Green Building Program has specifically recognized panelization construction as a leader in green and efficient building.

Precision Construction, Precisely on Time

There is really no comparison when it comes to time savings, cost efficiency, and precision construction. The cutting-edge engineering techniques and machines used to manufacture panel systems are doing in days what it would take an entire crew weeks to accomplish, with much less waste, increased reliability, accuracy and consistency.